Novel geometry reaching high efficiency for multiple injector concepts

G. Nyrenstedt, H.G. Im, A. Andersson, B. Johansson

SAE Technical Paper, 2019-01-0246, (2019)

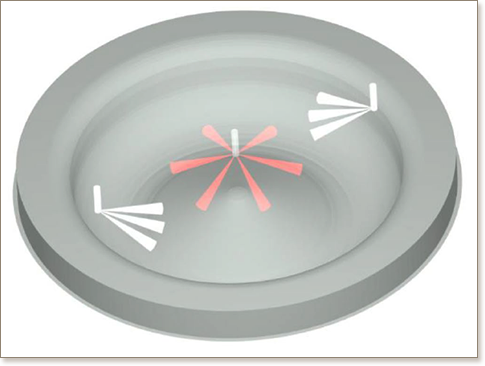

Heat losses are known to decrease the efficiency of CI engines largely. Here, multiple injectors have been suggested to shrink these losses through reduction of spray wall impingement. Studies on multiple injectors have proven the concept’s heat transfer reduction but also highlighted the difficulty of using a standard piston bowl. This study proposes a two-injector concept combined with a flat bowl to reduce heat losses further. To change the spray pattern, the two injectors are injecting in a swirling motion while placed at the rim of the bowl. Four injection timings have been investigated using Reynolds-Averaged Navier-Stokes simulations. This computational method quantified the amount of heat loss reduction possible. A conventional single injector concept is compared to two injector concepts with a standard and flat bowl. A Double Compression Expansion Engine (DCEE) concept, based on a modified Volvo D13 single-cylinder engine, was the base for all simulations. The DCEE can re-use the residual exhaust energy for a second expansion meaning increased importance of reduced heat losses. Heat release effects were discarded in the evaluation as an explanation for the reduced heat losses in order to isolate the effects of the changed spray pattern. Results showed a decrease in heat losses by 25.1 % or 4.2 % of the fuel energy as well as an increased IMEP of 4.5 % or 1.9 % of the fuel energy. Together with the increased exhaust energy, results showed a possible total engine efficiency increase of 2.6 % using the DCEE concept. This work successfully proves the benefits of using two injectors with a flat bowl over a standard bowl and the conventional one-injector strategy.